PEEK GF30 glass fiber filling - Suzhou Dotmar Engineering Things To Know Before You Get This

How Ketron® GF30 PEEK - Mitsubishi Chemical Advanced Materials can Save You Time, Stress, and Money.

904 W 6th Street, Shiner, TX 77984 Terms

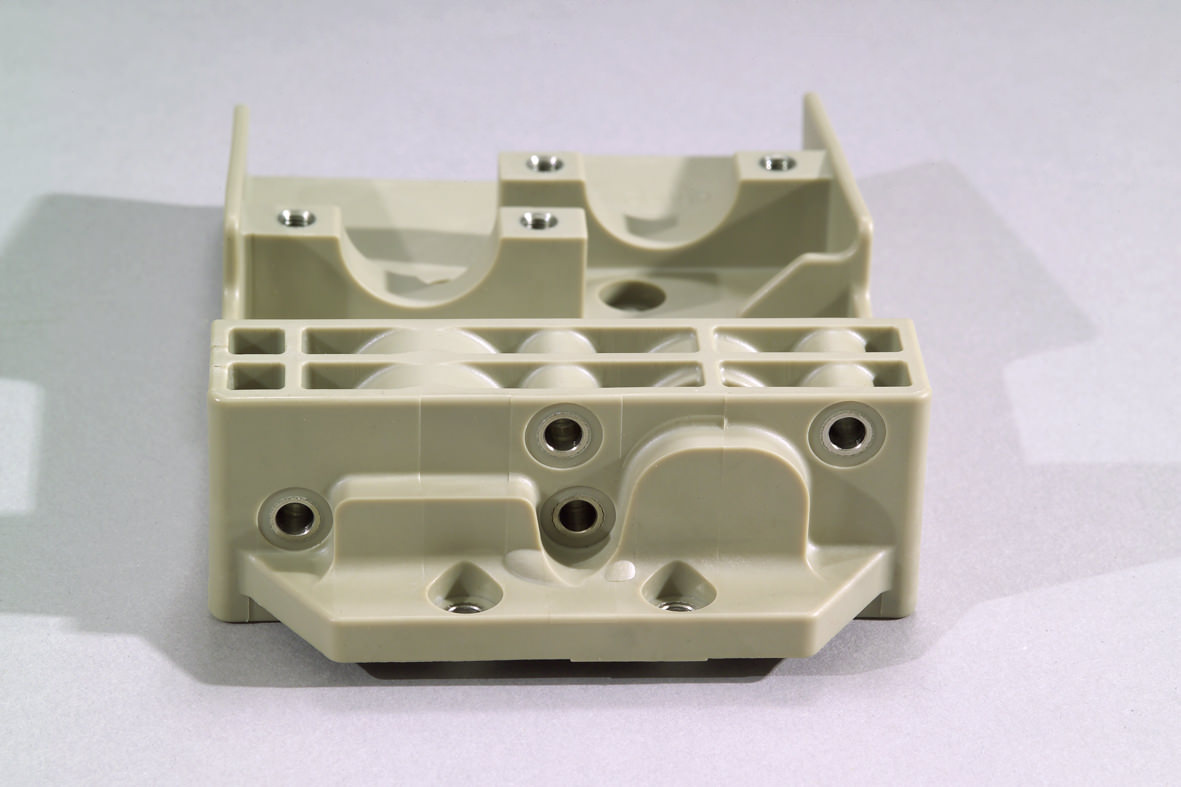

SHP PEEK GF30 Ultimate is a high-performance plastic strengthened with glass fibre. Just like The Most Complete Run-Down , PEEK GF30 Ultimate offers the exact same performance characteristics as our basic material, PEEK 450G, but with the addition of glass fibre, the efficiency qualities increase even further. GF30 integrates high rigidity with exceptional dimensional stability to provide really high tightness and enhanced durability.

Polyether Ether Ketone (PEEK): Properties, Production & Apps - Matmatch

Machining needs tipped tooling due to the plastics glass fibre material. Material Benefits GF30 provides outstanding efficiency qualities, that include: High Rigidness and good dimensional stability Higher compression capability Greater constant service temperature Very high stiffness and Improved toughness Best high static load over extended periods at high temperature Less ideal for bearing and use applications Motorsport Applications Applications for GF30 plastic consist of: Strut installs front and rear suspension Control arm linkages Equipment link bushes Fuel line insulators Valve components Electrical elements Chassis elements About Smiths HP We are a leading shareholder and provider of high-performance engineering materials to the motorsport sector.

Plastic Material PEEK GF30 - Plastic & Ceramic Screws - MISUMI

Not known Factual Statements About Ketron® LSG GF30 PEEK - Material Hub

This is a special 30% glass filled PEEK modification that Ensinger manufactures under the name TECAPEEK GF30 natural. In contrast to unfilled PEEK, this glass fibre enhanced product exhibitions increased mechanical strength and high rigidness. Furthermore, improved creep strength and dimensional stability are achieved by this glass filled PEEK. These properties make this product suitable for use in parts which are exposed to high static loads over long periods in high temperature conditions.

TECAPEEK GF30 uses exceptional chemical resistance, is insoluble in all typical solvents, and displays remarkable resistance to high dosages of gamma radiation. As with all PEEK grades, PEEK GF30 integrates high thermal stability with very little thermal growth and very low moisture absorption. As with all Ensinger PEEK products, we can verify that glass filled TECAPEEK GF30 natural meets the limitations enforced by Ro, HS Instruction 2011/65/EU Restriction of Hazardous Substances in electrical and electronic devices.

AKROTEK PEEK GF 30 natural (5047) is a 30% glass fiber strengthened medium viscosity polyetheretherketone with high stiffness and strength.

PEEK GF30

Some Known Details About PEEK GF30 glass fiber filling - Suzhou Dotmar Engineering

Any usage of this details falls under the rules of our disclaimer. Processing/Physical Qualities, Value, System, Test Requirement, ISO Information, Melt volume-flow rate, MVR 3. 5 cm/10min ISO 1133 Temperature level 360 C - Load 2. 16 kg - Melt flow index, MFI 4. 5 g/10min ISO 1133 Temperature level 360 C - Load 2.